In-Vessel Composting Machine

In-Vessel Composting Machine

What is In-Vessel Composting Machine?

An in-vessel composting machine performs a closed, aerobic fermentation process where organic waste is composted inside a drum bioreactor. The system controls composting parameters, allowing microorganisms to decompose organic matter under ideal conditions. In short, through composting, waste is transformed into an odorless soil conditioner called “compost.”

The process typically passes through:

-

Active Thermophilic Phase (55–65°C): Pathogens and weed seeds are destroyed.

-

Stabilization Phase: Organic matter breaks down into humus-like stable compost.

-

Curing Phase: Material matures and becomes suitable for soil application.

These phases occur automatically with the biological activity inside the drum.

Medium Scale In-Vessel Composting

Medium-scale systems are designed for capacities between 1–5 tons/day, making them ideal for:

Dairy, Poultry & Livestock Farms

Animal manure can be difficult to manage due to:

-

Odor emissions

-

High moisture content

-

Pathogen concerns

In-vessel composting machine helps farms convert manure into stable, pathogen-free organic fertilizer while significantly reducing odor and fly problems.

Food Processing Facilities & Supermarkets

Food factories, bakeries, fruit packing sites, slaughterhouses and supermarkets generate large volumes of organic waste every day. Landfilling this material is costly and environmentally harmful.

An in-vessel composter transforms food waste into valuable compost that can be used for landscaping, agriculture or biobased soil products.

Key benefits:

-

On-site waste reduction

-

Lower disposal and transport costs

-

Supports corporate sustainability programs

Restaurants, Hotels, Catering & Hospitality

The hospitality sector faces increasing pressure to reduce waste. In-vessel composting allows food scraps to be processed on-site, avoiding odor issues and keeping operations clean.

Hotels and resorts can use the resulting compost in:

-

Landscaping

-

Herb gardens

-

Local community gardens

This creates a closed-loop food system and enhances sustainability branding.

Municipal Waste & Community Recycling Centers

Cities and municipalities are seeking cost-effective ways to divert organic waste from landfills. In-vessel composters integrate smoothly into source-separated organics (SSO) programs.

They:

-

Reduce landfill methane emissions

-

Create high-quality compost for public green areas

-

Support circular economy initiatives

Small-to-medium installations fit well in urban or semi-urban environments.

Universities, Hospitals & Corporate Campuses

Facilities with cafeterias generate food waste daily. Instead of relying on external waste hauling, in-vessel systems allow on-site waste treatment.

This:

-

Lowers operational waste costs

-

Provides educational sustainability value

-

Produces compost for campus landscaping

Such installations often become flagship sustainability showcases.

Remote Communities & Islands

Transporting organic waste to centralized facilities can be expensive and logistically difficult. In-vessel composters offer a self-contained waste management solution where infrastructure is limited.

They support:

-

Local agriculture

-

Community gardens

-

Reduced import of chemical fertilizers

In-Vessel Composting System Solution

Compost Production Process

Compost Discharge from In-Vessel Composting Process

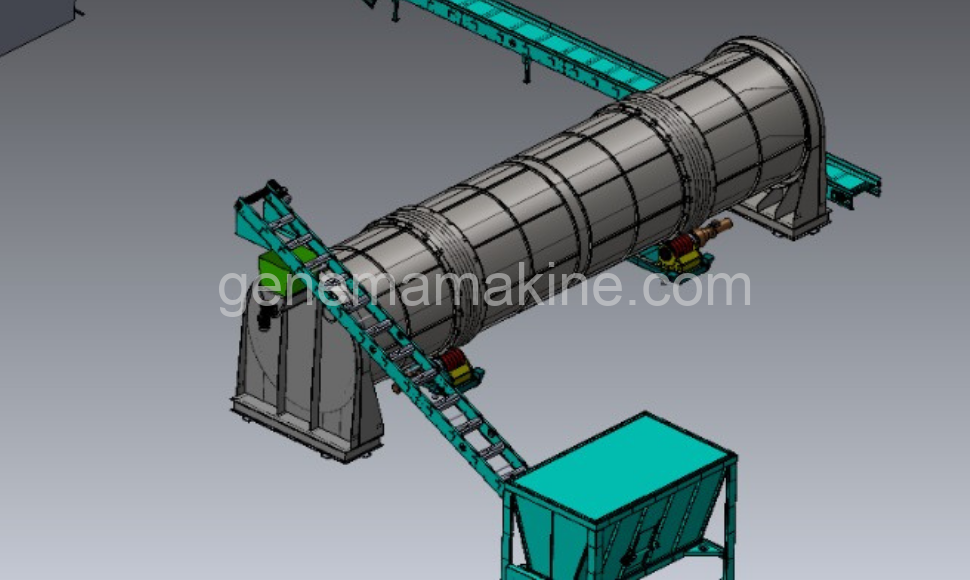

Medium Scale Composting Line

| 1 | Organic Waste Feeding Conveyor |

| 2 | Organic Waste Feeding Bunker |

| 3 | Composting Bioreactor Feeding Conveyor |

| 4 | Medium Scale Composting Bioreactor |

| 5 | Compost Discharging Conveyor |