Large Scale Composting System

Large Scale Composting

Large Scale Composter Features

Large Scale Composter is a fully automatic in-vessel composting system designed to process of organic waste in open or covered halls. It operates on the agitated bed principle, similar to advanced windrow and tunnel turners, providing continuous mixing, aeration, and material movement from the beginning to the end of the hall.

- Fully automatic system for large-scale organic waste processing.

- Continuous agitation ensures consistent aeration and uniform composting.

- Energy-efficient design with low power consumption per ton.

- Material flows smoothly from inlet to outlet through the entire hall.

- Rapid composting cycle.

Large Scale Composting Operation

The operation of a large-scale composting facility is typically as follows:

Organic Waste Feeding and Distribution

Organic waste is first delivered into the Feeding Bunker, where the material is weighed and homogenized. From here, Hall Feeding Conveyors distribute the feed evenly along the composting hall. The feeding is fully synchronized with the composter’s working cycle, ensuring a consistent layer height.

Composting and Agitation Process

Inside the composting hall, the Large Scale Automatic Agitated Bed Composter travels slowly along the rails over the composting bed.

Its powerful mixing blades continuously agitate the material, ensuring:

- Complete aeration and oxygen distribution throughout the pile,

- Uniform temperature and moisture across the entire bed,

- Prevention of clumping and anaerobic zones,

- Continuous forward movement of the composted material.

The turning mechanism is inverter-driven for variable speed control, while a hydraulic system lifts or adjusts the mixing drum to maintain the desired working depth. The process is fully automatic and monitored through a PLC-based control system with touch-screen HMI and Wi-Fi connectivity.

Material Flow and Residence Time

As the composter moves forward, freshly fed material is mixed at the front, while partially composted material advances toward the discharge end. This creates a plug-flow effect, where the material continuously progresses through thermophilic and maturation phases within the same hall.

Compost Discharge and Transfer

At the end of each cycle, the Hall Shuttle automatically transfers the composter to the next hall.

The mature compost is discharged via conveyors for packaging.

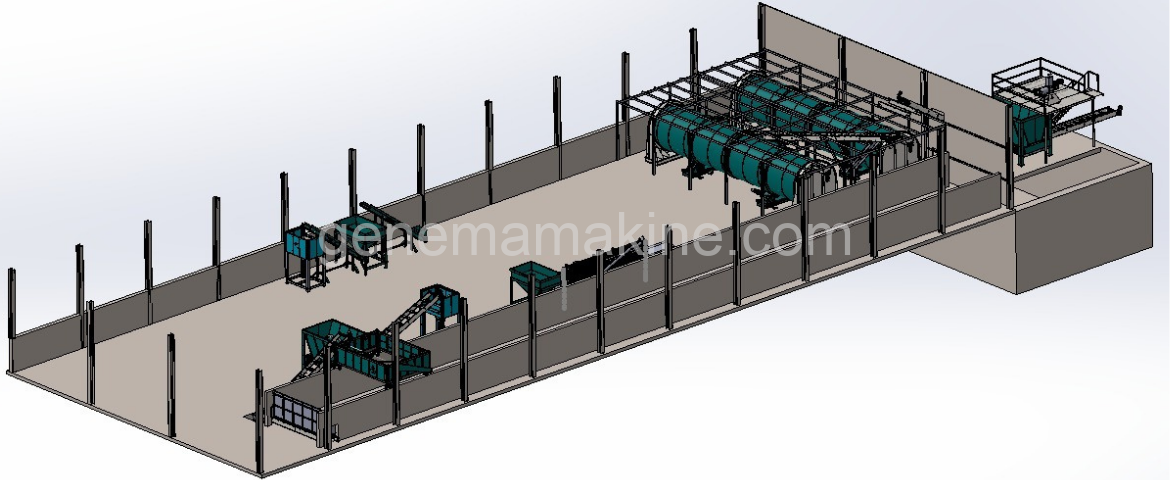

This modular, multi-hall setup allows continuous operation while one hall is being filled, others remain in active composting or discharge mode.

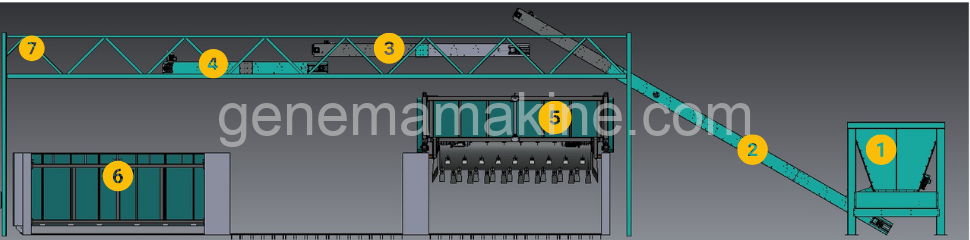

Large Scale Composting Machine

Agitated Bed Composter

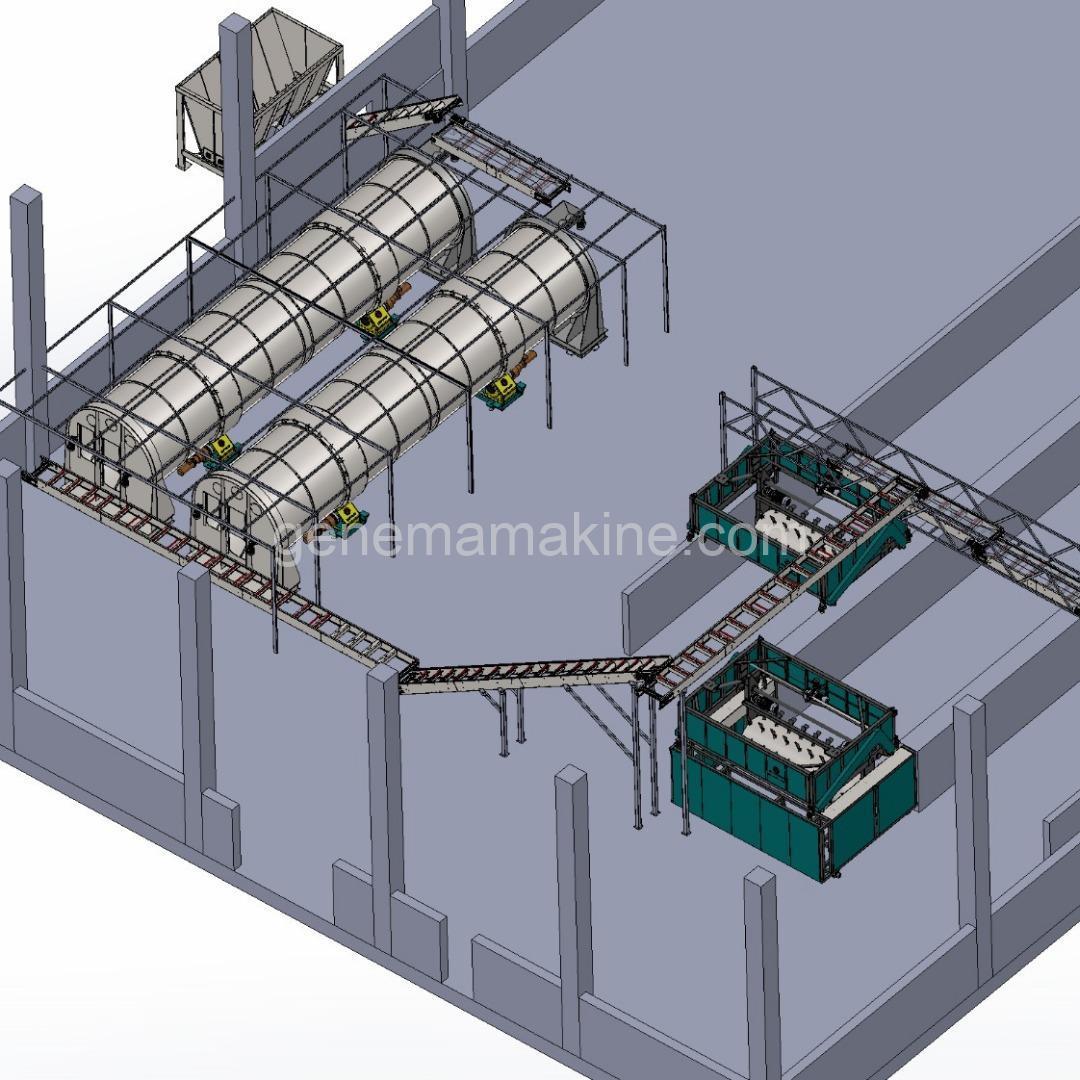

3D Composting Plant

Composting Plant Components

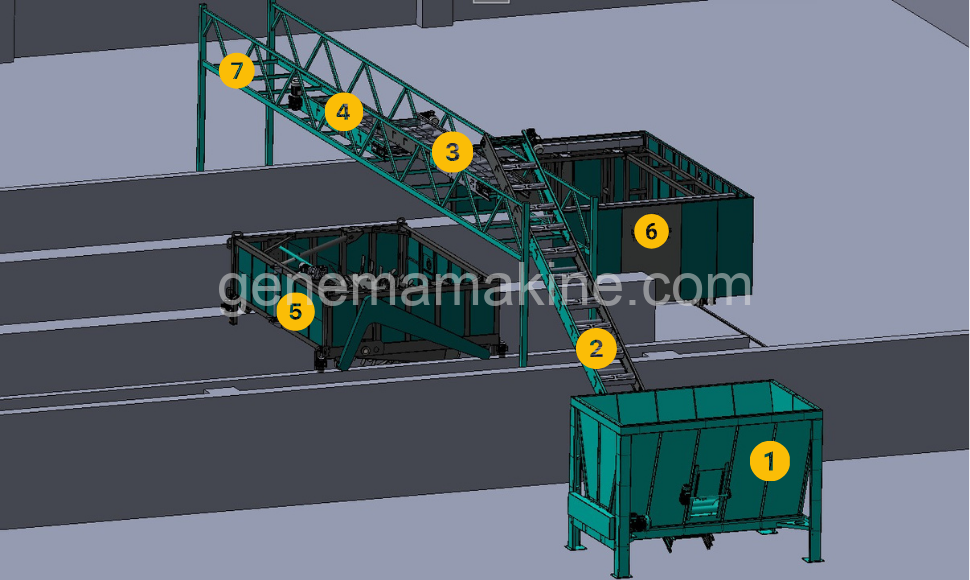

Complete Composting Line

| 1 | Feeding Bunker |

| 2 | Discharging Conveyor |

| 3 | Hall Feeding Conveyor-1 |

| 4 | Hall Feeding Conveyor-2 |

| 5 | Automatic Composter |

| 6 | Hall Shuttle |

| 7 | Steel Platform |

| 8 | Collecting Conveyor |

| 9 | Feeding Conveyor |

| 10 | Stock Bunker |

| 11 | Discharging Conveyor |

| 12 | Feeding Bunker |

| 13 | Feeding Conveyor |

| 14 | Packing System |

Hybrid Composting System-

Bioreactor & Large Scale Composter Integration

Hybrid Large Scale Composting System Advantages

The hybrid operation of a composting bioreactor and a large scale composter (agitated bed composter) represents the next generation of organic waste processing technologies.

By combining the controlled environment of a bioreactor with the mechanical agitation and aeration of an agitated bed composter, this integrated system achieves rapid compost stabilization, reduced odor, and optimized energy consumption.

Composting Bioreactor Effect

The hybrid type composting system significantly reduces the overall process time by dividing composting into two efficient stages.

First, microorganisms in the composting bioreactor start the thermophilic phase immediately and raise the temperature within a few hours.

They actively decompose organic matter while the aeration and humidity control units maintain ideal oxygen and moisture levels.

As a result, the bioreactor completes the initial breakdown in just one to three days.

Afterward, operators transfer the partially composted material to the Automatic Agitated Bed Composter, where the process continues without interruption.

Here, mechanical paddles continuously mix and aerate the material, ensuring uniform oxygen distribution and consistent temperature across the composting bed.

Meanwhile, the composting mass gradually moves forward through the hall, allowing complete aeration and stabilization.

Typically, the agitated bed stage finishes in twenty to thirty days, depending on the feedstock and desired moisture level.

Consequently, the hybrid system reduces the total composting time by nearly half compared to conventional single-phase processes.

Moreover, it enhances process flexibility, since operators can adjust the retention time in the bioreactor to balance throughput and compost quality.

Ultimately, this integrated approach accelerates decomposition, saves energy, and delivers a uniform, high-quality compost in a significantly shorter period.

Typical Feedstocks

-

Animal manure: poultry, cattle, camel, horse and pig manure with or without bedding materials.

-

Agricultural waste: crop residues, husks, straw, and bagasse.

-

Municipal organic waste (OFMSW): collected household organic fraction after sorting.

-

Sewage sludge and digestate: dewatered sludge and anaerobic digester outputs.

-

Green waste: grass clippings, leaves, and pruning residues.

In-Vessel Composting Bioreactor

In-Vessel Composting Bioreactor for Industrial Composting Process

Hybrid Type Compost Production Facility

Bioreactor Discharge & Agitated-Bed Integration

Integrated Composting Line

Would you like us to compost your organic waste?